Story by Rick Vacek

Photos by David Kadlubowski

GCU News Bureau

Canyon Promotions makes all sorts of promotional products, especially T-shirts. Lots and lots of T-shirts, mainly for Grand Canyon University events.

But it certainly had never made the face masks that have become a COVID-19 necessity. On top of that, the staff was working at home because of the pandemic.

So when Renate Spilger, Enterprise Division Manager for Canyon Promotions, was asked by GCU’s Emergency Preparedness Task Force whether it was possible for her team to produce cloth masks for the campus and GCU’s community partners, it was far more than just another T-shirt order.

It didn’t get any easier when industry experts, including the manufacturer of her embroidery machine, said it couldn’t be done.

End of story? Hardly. It was only the first chapter.

“I’m German – I’m stubborn,” she said. “They say it can’t be done and I say, ‘Watch me.’”

Clearly, Spilger has fully invested in the can-do GCU spirit in just eight months on the job. She convened her team for a Zoom meeting and watched one idea lead to another.

“In the beginning, it was a little bit hesitant, like, ‘If everybody says that it can’t be done …’ But then it just started exploding from there,” she said. “Everybody was bringing a lot of enthusiasm and changes and updates. The input was just amazing, all through Zoom and emails.”

That all happened within 10 days, and by last week Canyon Promotions was producing as many as 350 masks in a day. Just like that.

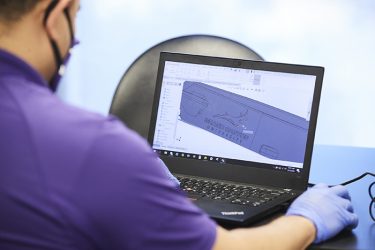

The collaboration was equally constructive in the College of Science, Engineering and Technology (CSET) when its dean, Dr. Mark Wooden, brought together his team to figure out how to use its 3D printers to make other personal protective equipment (PPE), such as plastic face shields and respirators.

“Mark is very good at bringing us all together,” said Dr. Janet Brelin-Fornari, Associate Dean of Engineering. “With his background, especially at this University, he can receive all the pieces that need to come together to make the project successful and make it look seamless.”

In equally efficient fashion, CSET already is ramping up to 700 face shields a week while it works to perfect the design for the respirators. It became even more of a win-win when it fulfilled another mission of the University – providing hands-on learning experiences for students.

Brayley Fleetwood normally is an anatomy lab assistant but was recruited to help with the PPE project, which fits perfectly with her major (pre-med) and career goal (emergency room trauma physician).

“It’s really cool to be able to see all the different aspects of this type of thing,” she said. “This is information that is only going to help me in the future, especially with the profession I want to go into.”

Within a day, Fleetwood had learned how to operate the 3D printers – CSET is using about two-thirds of its 42 printers for the project – and was able to assist Lab Supervisor Jude Fernando.

She was learning. But so is Fernando.

“The project has been enjoyable,” Fernando said. “It’s a team activity, so there are a lot of different people who need to be involved. Who will help you out? What are our goals?

“Just getting all those people together and agreeing on something has been the biggest accomplishment, combining what we want to do with who we want to serve.”

The need for such teamwork became even more acute when the first COVID-19 case on the GCU campus was discovered last week. The Emergency Preparedness Task Force had established strict guidelines for such a scenario, including isolating the infected student and anyone the student had been around.

“We are blessed that it took this long to have our first COVID-19 test result, but it was only a matter of time,” said Marcus Castle, Emergency Preparedness Manager. “You always hope for zero, but it’s a good test for us in preparation for reopening the campus, whether it’s in the summer, fall, whenever it might be, that we have our plans and procedures in place.”

When the Task Force sat in on a national conference call last week to discuss items universities should be taking into consideration, its members were heartened by the fact that they already were doing all those things.

“I think we can compare our plans to anybody else around the United States,” Castle said. “We have, if not the best, one of the best infectious disease plans.”

Also last week, the Canyon Health and Wellness Clinic put into effect new telehealth policies (see story here). “We have minimized our exposure,” said Connie Colbert, the clinic’s director. “We changed some of our policies. You can’t just walk in the clinic – you have to call ahead.”

But no unit on campus has had to change more on the fly than Canyon Promotions. Friday, for example, Jake Bradshaw was performing a first-in-his-life task: He was cutting elastic for the bands from the masks that hook around your ears.

“Didn’t think I’d be cutting elastic and T-shirts, but here we are. Pandemic … duty calls, right?” said Bradshaw, the former Havocs Co-President who has worked for nearly a year as a customer solutions representative, accountancy specialist for Canyon Promotions.

Like the rest of the team, Bradshaw was at home working with customers on future orders when the call came in to produce masks. Also like his co-workers, he welcomed the opportunity.

“It was unique for us,” he said. “We all wanted to volunteer and pitch in. We all picked up a box of T-shirts and brought it home and cut them out into the shape of masks and brought it back here so Maribel could sew them together.”

Maribel Espinoza operates the embroidery machine – the one the manufacturer said couldn’t be adapted for this project. It took her a few days to figure it out, but then she found solutions and more solutions.

“Once you get used to it, you start thinking of other ideas. ‘OK, this could work better … let me try it … it works … OK,’” she said. “If it shaves off a couple of minutes per mask, why not?”

It’s no wonder Spilger feels so blessed to be in her role and to have such a strong team. She is a 27-year veteran of the graphics industry, and Canyon Promotions was one of her clients when she heard about the job that was available.

“Literally by accident I stumbled into this opportunity and knew half the team, knew my way around campus,” she said.

Now she is seeing, firsthand, how that campus faces up to a crisis – even one that requires covering your face. It didn’t take much prompting for boxes of unused T-shirts to start coming in from all over campus.

“We just took what we had,” she said, “and created something that is pretty cool.”

And the coolest part of all: They accomplished something that they said couldn’t be done.

Contact Rick Vacek at (602) 639-8203 or [email protected].

****

Related content:

GCU Today: GCU contributing to coronavirus relief efforts

GCU Today: Student enterprises blend energy, opportunity

GCU Today: New engineering leaders bring industry savvy to GCU

GCU Today: Sure bet: ABET appointment a boon for GCU