By Lana Sweeten-Shults

GCU News Bureau

Sitting in a chair for 90 minutes listening to the sing-song drones of a lecture.

That’s exactly how Cory Cathrea, junior electrical engineering major, didn’t want to spend all his time at Grand Canyon University. He wanted to do something fun outside the classroom.

“I wanted to find a project that I could funnel my love for engineering into, but also apply much of the concepts I have learned while in school,” he said.

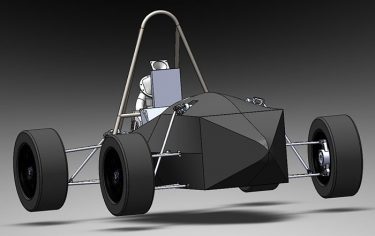

Cathrea, president of the student branch of the electrical engineering club, officially known as the Institute of Electrical and Electronics Engineers (or “the I triple E,” as its members call it), started searching for a cool project to tackle. He found one: building a scaled-down model of a Formula 1 vehicle for the Formula SAE Collegiate Design Series competition June 19-22 in Lincoln, Neb. During the event, presented by the Society of Automotive Engineers International, university undergraduate and graduate students conceive, design, manufacture and compete with small, Formula-style vehicles.

“This is really, really exciting for the University and the engineering program,” said Dr. Kevin Williams, who teaches mechanical engineering and is the faculty advisor for the 30-plus-member GCU Formula SAE Team. “It is the first time ever we at GCU are going to have a Formula vehicle built for competition.”

The team added how it's "hungry to make an impact" by applying engineering fundamentals to "create a vehicle worthy of Grand Canyon University."

Students spent eight months designing the vehicle, which rocks the number 76, on a computer-aided design and engineering program called Solidworks. The team raised $8,300 for the build from corporate sponsors Vector Launch, Jones Brothers Construction, Voodoo13, STAX3D and MobilTape and from friends and family.

The first-year team started fabricating the car in January and hopes to complete it in time for two months of testing before leaving for Nebraska.

They’ll be eyeing automotive glory, and, of course, bragging rights, by pitting themselves against a field of 80 universities.

The competition will be tough, Williams said. Other universities they’ll be facing are well-versed in this event: “They will be competing with teams that have been doing this for years and years.”

The team must go through the rigors of a slew of technical inspections in the first two days. Over that span, judges will evaluate the team's ability to apply engineering design concepts, the cost of the vehicle and the ability of the team to present a business plan based on their unique vehicle. On the other two days of competition, the entrants will compete to test the handling, safety, acceleration, efficiency and performance of their vehicles against the 79 other teams at the competition.

Building a car as cool as a formula-inspired vehicle has been that fun element Cathrea and his fellow team members have hoped for, but at the same time, it will be something to show employers, too.

“They look for projects in your portfolio, and this is one of those projects,” Cathrea said.

Fabricating a winner

It’s noon on a recent Tuesday.

Do you know where your electrical and mechanical engineering students are?

Well, if they’re at GCU, they’re in one of the labs peppering the College of Science, Engineering and Technology Building.

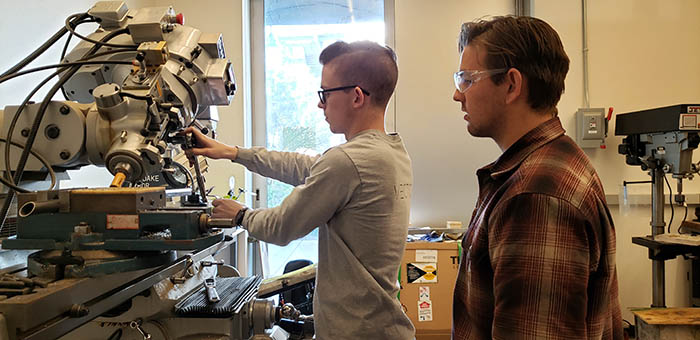

The Formula SAE Team is prepping for the day's build, occupying two labs on the first floor. Students are divided so they can tackle the design and manufacturability of different systems in the vehicle.

Dillon Kayl, a junior electrical engineering major, is using industrial-grade machinery to cut through a tube of steel that will make its way onto the chassis of the car.

“Did you measure from the tip of this?” asks Cathrea, who worked as a manufacturing intern at Vector Launch in Tucson and at an electric vehicle company called Lucid Motors in Fremont, Calif.

“You measure twice, cut once,” said Kayl with a smile.

He joined GCU’s Formula SAE Racing Team because a few of his friends are involved in the group -- plus he loves cars (he has worked as an automotive technician).

He also wanted to do something unique in between homework and studying for exams.

“I like being able to do something outside the box,” said Kayl, who is part of the team’s differential systems group, which makes sure power from the car’s motor gets to the wheels. “It’s not every day you get to go to school, cut (with heavy machinery), build a race car and then go to math class afterward.”

While Kayl does fabrication work, freshman electrical engineering major Adriana Sweeney is on the other side of the lab working with junior mechanical engineering major Brian Holm, lead of the team’s brakes crew.

Sweeney, whose father is an engineer, never has worked on a car before, but “it’s crazy how much I actually enjoy it,” she said of the project, adding how it’s her dream to work at Tesla.

So far Sweeney’s contribution has been to design the push bar, which goes on the rear of the vehicle to protect it from collisions.

Her favorite part of the process is seeing the project slowly come together, she said, adding, “I love working with these guys; these guys are all like my brothers.”

While Sweeney had the chance to design the push bar, Holm did the same with the brake rotors.

“I don’t have a lot of hands-on experience,” he said. “I kind of knew what I was doing, but I had to research.”

It is the first time he’s been in a leadership role.

“What I’ve learned the most is, actually, leadership skills. I really hadn’t had the chance to lead a team like this,” Holm said.

Exceptional team

What has impressed Williams about this project is just how capable the students have been.

“This team is an exceptional group of students,” he said, emphasizing how team members have taken control of the project since the beginning and have been focused on carrying out their vision. “It’s their car. They’ve been responsible for designing it, complying with the rules and communicating with SAE to make sure they meet the timeline for the competition.”

They’ve also done a “phenomenal job,” he added, of sourcing sponsors and finding partners to work with in helping the team with components needed for the vehicle.

“They’ve been proactive with the community and local industry to pull those things together,” he said.

With just 2 1/2 months left before the competition, the students are ramping up to get the build done and move into the testing phase as they set their sights on Nebraska.

Williams said, “I’m thrilled to death to see how our students will stack up.”

***

Related content:

GCU Today: "GCU club engineers hope for Ruby"

YouTube: Grand Canyon University IEEE Student chapter Appropriations Video